Why Are My Labels Printing Out Of Alignment? From Causes to Steps

Whether it is the identification of hundreds or even thousands of network cables in the communication room or the safety warnings and numbers on power equipment, they all need to be printed through labels to ensure standardized management and clear information. However, in actual operation, many engineers often encounter a confusion: why are my labels printing out of alignment? The printed content is either left or right off the mark, or the top and bottom positions are inaccurate. This not only affects the accuracy of the equipment marking but may also cause repeated rework and even delay the project progress. Such problems may seem minor, but they are sufficient to affect the entire workflow.

Common Reasons For Misaligned Label Printing

To answer the question “Why are my labels printing out of alignment“, we need to first identify the root cause of the problem before looking for a solution. Label printing out of alignment is often not accidental, but rather caused by several factors:

1. Printer Settings issue

In many cases, the problem lies in the matching of software and printer parameters. If the paper size, print direction or margin Settings are incorrect, it will result in the printed content not matching the actual label position.

2. Paper and label issues

The quality of the label paper itself is also very crucial. If the thickness of the label paper used is uneven or the material is incompatible with the printer, it is very likely to shift. In addition, if the label is not accurately positioned when being loaded into the paper slot, it will also directly affect the printing alignment.

3. Hardware factors

With the long-term use of the printer, the rollers may wear out and the print head may also shift slightly. These hardware issues will all cause unstable tag delivery, thereby leading to misalignment.

4. Issues with operational habits

Sometimes the problem is not the equipment itself, but rather the non-standard daily operation. For instance, failing to calibrate the printer in a timely manner or neglecting regular cleaning of the equipment can both pose hidden dangers.

Solutions For Misaligned Label Printing

Knowing the reason, we can then solve the problem in a targeted manner. The following several methods can help you quickly troubleshoot and improve the printing effect

1. Check the print Settings

First, enter the printing software or driver and confirm that the paper size is exactly the same as the label specification. Secondly, check if the margins and print direction are correct. If necessary, you can conduct a one-page test print first.

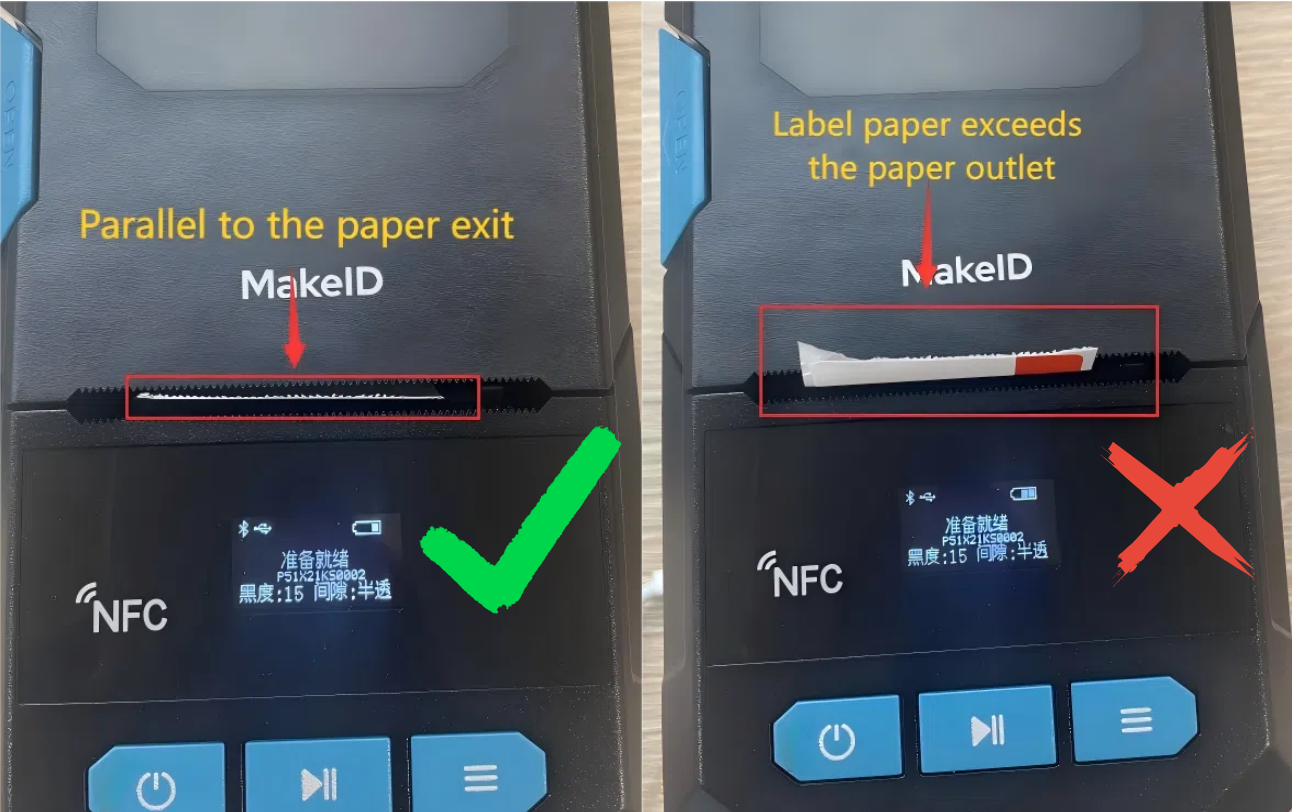

2. Adjust or replace the label paper

If you find that the offset problem keeps recurring, you might as well try replacing it with higher-quality label paper. When loading the paper slot, make sure the label is aligned with the guide rail to avoid tilting.

3. Calibrate the printer

Most label printers are equipped with automatic or manual calibration functions. By running the calibration program, the printer will re-identify the label spacing and size, thereby improving the alignment accuracy.

4. Clean and maintain hardware

Regularly clean the rollers, conveyor belts and print heads of the printer to prevent the accumulation of dust or paper scraps from causing conveying deviations. Check if the print head needs adjustment. When parts are found to be severely worn, replace them in time.

5. Use professional software for assistance

Some professional label design software offers precise template Settings, which can help users complete typesetting and proofreading before printing. Saving the adjusted template well can also avoid errors caused by repeated Settings each time.

Tips for Preventing Misaligned Label Printing

Compared with frequently correcting mistakes, taking preventive measures in advance is obviously more time-saving and labor-saving. The following few tips are worth persisting in for a long time:

- Regularly maintain the equipment: Keep the printer clean to extend its service life.

- Choose regular consumables: Use brand label paper to avoid deviation caused by substandard materials.

- Test before printing: Print one sample page first. After confirming that there are no errors, print in batches.

- Establish fixed templates: Save print templates for commonly used labels to reduce the risks caused by repeated Settings.

When Is Professional Support Needed?

If you have tried the above methods but still frequently encounter misalignment issues, the problem may lie in a deeper hardware failure. For instance, inaccurate positioning of the print head, severe wear of the rollers, etc. In this case, it is recommended to contact professional after-sales service or technical personnel in a timely manner to avoid the problem being delayed and affecting normal work. For enterprises, if there is a demand for large-scale and high-precision label printing, they can also consider upgrading to printers with higher performance.

Summary

Why are my labels printing out of alignment? Solving this problem is not complicated, the key is to be patient and investigate. Most problems can be improved by checking the print Settings, optimizing the label paper selection, calibrating the printer and doing a good job in daily maintenance. At the same time, developing good operating habits can not only reduce deviations but also significantly enhance work efficiency.

In other words, only by identifying the cause and making timely adjustments can the label printing always remain clear, neat and professional.