Top 3 Types of Labels for Cables and Wires

Cable labels are the unsung heroes in the world of telecommunications, power and even healthcare. They are not simply markers, but rather the lifeblood for quick troubleshooting and strict regulatory compliance. In highly sensitive areas like surgical wiring and high-voltage grids, the wrong choice results in peeling, fading, and expensive downtime. Let’s take a look at the 3 main types of labels that will keep your infrastructure orderly, secure and looking good.

Top 3 Types of Labels for Cables and Wires

| Label Type | Core Features | Ideal Scenarios |

| Heat-Shrink Cable Labels | Heat-shrinkable, integrated adhesion, -40℃~125℃ tolerance, wear/chemical-resistant | Outdoor high-voltage cables, railway/ship wiring, industrial equipment |

| Self-Laminating Cable Labels | Built-in film, scratch-resistant, easy to install, curved surface-friendly | Data centers, medical equipment, office/commercial weak current cabling |

| Flag Labels | Flag-shaped, high visibility, flexible installation, multi-line printing | Dense data center cabling, residential/office weak current wiring, small device internal ca |

1. Heat-Shrink Cable Labels – The “Protection King” with Integrated Adhesion

Heat-shrink cable labels are the most unique ones as they connect the cables in the most efficient manner. Heat-shrinkable material is used to make these labels and they are heated to contract tightly around the cables, thus, forming a unit that is wrinkle-free and without edges, which is thus, able to resist peeling. Their protective performance is nightmarish for any foe: They are highly wear-resistant, stretch-resistant, and chemical-resistant therefore they can do well in harsh industrial environments and outdoor use even for a long time, temperature-wise they can take up to -40℃ to 125℃.

Perfect for the hardest conditions:

- Power Engineering: Cables with high voltage for outdoor use of State Grid/China Southern Power Grid and trench cable (hard to extrude, moisture, and salt spray resistant).

- Transportation: Rail train wiring and ship equipment cables (can take the vibrations and alternating high/low temperatures).

- Industrial Equipment: Central cables of big machines, automated production-line, and petrochemical industry (oil-and-mechanical-friction resistance).

2. Self-Laminating Cable Labels – The “Convenient Choice” for Scratch Resistance

Self-laminating labels for wires come with an overhead film that is transparent. The label is to be printed first and then the round cable is covered up by the printed area of the so-called “label + protective film” structure. There are no additional tools required—they are easy to install, scratch and smudge resistant, and perfectly fit the rounded surface of the wires.

Ideal for indoor situations:

- Offices & Data Centers: The network cabling for the company and the cables for the big data cabinets (helping with a tidy, low-maintenance labeling process).

- Healthcare: Internal wiring of the medical equipment in the hospitals (having a disinfectant proof and handling wear resistant coating).

- Commercial Venues: Weak current cabling in shopping malls, office buildings, and indoor communication base stations (making it easier to maintain later).

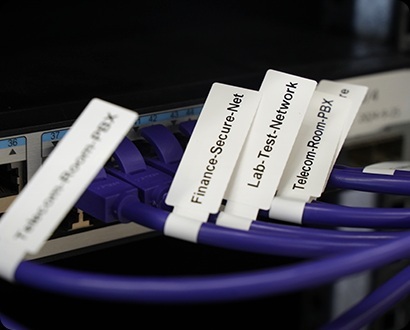

3. Flag Label – The “Identification Tool” with Strong Visibility

Flag labels have a typical “flag-shaped” design—their central part can be folded or positioned vertically, with the printed area facing up, which allows for quick identification in thick cables (it means no more flipping wires). They are flexible for installation as they can be wrapped around the cables without limiting their bending, plus they provide a lot of space for multi-line printing (for example, cable numbers, uses, maintenance dates).

Perfect for dense cabling:

- Data Centers & Server Rooms: Sorting out cable purposes by quickly distinguishing server clusters and switch connections.

- Weak Current Engineering: Cabling in office buildings and residential neighborhoods (like network/monitoring cables, thus more straightforward property maintenance).

- Small Equipment: Keeping track of the internal wiring of printers, routers, and small industrial devices (without blocking interfaces, intuitive labeling).

How to Choose the Right Cable Label? 3 Steps to Precise Matching

1. Choose by Environment

| Scenario Description | Recommended Label Type |

| Outdoor/harsh conditions (wind, rain, high temperatures, oil pollution) | Heat-Shrink Cable Labels |

| Dense indoor cabling (need for quick identification) | Flag Label |

| Indoor/outdoor scenarios requiring scratch/corrosion resistance | Self-Laminating Cable Labels |

2. Choose by Usage Needs

| Usage Requirement | Recommended Label Type |

| Long-term protection (5+ years, stable performance needed) | Heat-Shrink/self-Laminating Cable Labels |

| Temporary labeling/dense cable differentiation | Flag Label |

| Round cables needing tight adhesion (no wrinkles/edges) | Heat-Shrink/self-Laminating Cable Labels |

3. Choose by Printing Method

| Printing Scenario | Recommended Label Type |

| On-site/instant printing (construction/maintenance) | All three label types |

| Batch prefabrication/factory production | Heat-Shrink/self-Laminating Cable Labels |

The Label Printers Making it all Possible

Every trustworthy cable label is made with a high-performance printer, MakeID’s portable label printers are intended to give seamless results. The industrial-grade M400A, the user-friendly W110, and the versatile M200D/M200C model are designed to fit well with their labels in terms of delivering clear prints, strong bonding, and on-site efficiency. MakeID label printers have been trusted by giants like China Mobile, State Grid, and the best hospitals, and they are part of the diverse industries supported by these printers—from telecommunications and electric power to healthcare, industrial manufacturing, and more. MakeID’s one-stop solution with its compatible consumables, cancels compatibility problems, thus making the professional cable labeling possible in any situation.

Trying to pick the right one from the top 3 types of cable and wire labels? MakeID’s all-in-one “label + printer + consumables” solution takes all the guesswork out of it! Whether you go for heat-shrink, self-laminating, or flag labels, this integrated setup totally eliminates product mismatches and compatibility headaches—no more stressing over whether your gear works together. And since MakeID’s reliable labeling solutions are tailored specifically for these three core label types, you can relax knowing your cable identification is spot-on, your operations stay safe and compliant, and your infrastructure runs smooth as silk.