Thermal Label Paper And Thermal Transfer Label Paper: Durability Analysis

In the fields of warehousing and logistics, retail, manufacturing and asset management, labels serve as the “identity markers” of items. The clarity and durability of information are directly related to the smooth operation of business. However, problems such as fading labels and blurred handwriting are not uncommon, which not only lead to information loss but also slow down operational efficiency. The core of this issue often lies in the insufficient understanding of the technical characteristics of label paper.

Thermal and thermal transfer are the two mainstream printing technologies at present. The essential difference between the two directly determines the lifespan performance of labels throughout their entire life cycle, from the storage stage to actual use. Next, we will meticulously break down the storage shelf life and post-printing storage duration of these two types of label paper to help you accurately select high-quality labels that meet your needs.

How Long Can Blank Label Paper Be Stored?

The storage life of blank label paper directly affects the purchasing strategy and cost, which is often overlooked.

Thermal label paper: Inventory needs to be controlled

- Storage life: Relatively short. It is recommended to be used up within 1-2 years.

- The reason is that its sensitive thermal coating will naturally age over time and is sensitive to temperature, humidity and light.

- Risk: Long-term storage, especially in adverse conditions, may cause the entire roll of paper to spontaneously turn yellow and the background color to deepen, resulting in unclear printing or complete failure.

- Suggestion: The “first in, first out” principle must be followed to avoid large-scale hoarding.

Thermal transfer label paper: Stable and available for long-term stock

- Storage life: Very long, usually 3 to 5 years or even longer.

- The reason is that its base material (paper, synthetic materials) has stable chemical properties and its performance does not deteriorate over time.

- Risk: Mainly lies in moisture-proofing and dust-proofing. Moisture may affect the adhesion effect of the carbon ribbon.

- Suggestion: Suitable for bulk purchasing, with low warehouse management costs, it is a reliable choice for long-term inventory preparation.

General storage conditions: Temperature 18°C-26°C, humidity 40%-60%, away from light and heat, and stored horizontally.

Core Differences: Printing Principles and Shelf Life

Understanding the printing principles of thermal paper and thermal transfer paper is the foundation for understanding all their performance differences.

Thermal Label Paper:

- Principle: Its surface is coated with a special thermal coating. When the print head heats up and comes into contact with the coating, a chemical reaction occurs, causing the contact points to darken, thus revealing text or images.

- Shelf Life: This chemical reaction is reversible and unstable. Therefore, the shelf life of thermal paper after printing is relatively short, typically 6 months to 2 years. It is extremely sensitive to the environment; exposure to heat, light, friction, or chemical solvents (such as alcohol and grease) will cause it to fade or darken rapidly.

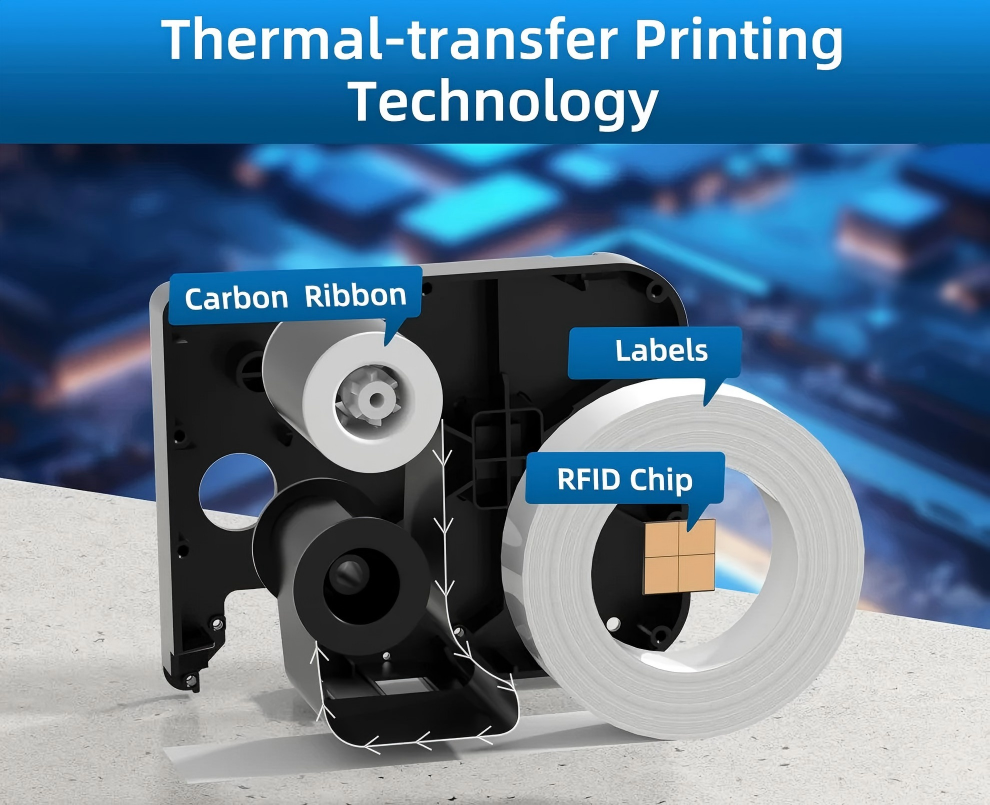

Thermal Transfer Label Paper:

- Principle: It is made of ordinary materials (such as coated paper, PET, etc.). During printing, the print head heats up, melting the solid toner on the ribbon and precisely transferring it to the label surface. After cooling, a strong adhesion is formed.

- Shelf Life: This is a physical process; the toner becomes part of the label. Therefore, its shelf life after printing is extremely long, reaching more than 2 years or even permanently. Its durability depends on the choice of carbon ribbon (wax-based, mixed-based, resin-based), which can be customized for different environments (friction, chemicals, high temperature).

Durability Comparison of Thermal Paper and Thermal Transfer Paper

| Characteristics | Thermal label paper | Thermal Transfer Label Paper |

| Retention period after printing | Short (6 months – 2 years | Long (from more than 2 years to permanent) |

| Storage life | Shorter duration (recommended to be used up within 1-2 years) | Relatively long (more than 3 to 5 years |

| Cost | Only label paper is needed, and the equipment and usage costs are low | It requires label paper and carbon ribbons, and the cost of equipment and consumables is high |

| Core advantage | Fast printing speed, quiet and simple equipment | Strong durability and capable of printing on various materials (synthetic materials) |

| Applicable materials | It is mainly thermal paper | Extremely wide range (paper, PET, PVC, fabric labels, etc.) |

| Typical applications | Receipts, express delivery slips, indoor labels | Asset identification, industrial labels, outdoor labels, chemical labels |

| Main causes of failure | Heat, light, friction, chemical substances | It mainly depends on the type of carbon ribbon |

| Moisture and heat resistance | Generally, it tends to turn black or fade easily | Excellent (Resin-based performance is outstanding |

| Wear resistance | Generally, it is prone to blurring | Excellent (especially mixed base/resin base) |

| Chemical resistance | Poor (afraid of alcohol, oil and solvents) | Superior (Resin-based, resistant to chemical corrosion |

| Resistant to outdoor ultraviolet rays | poor | Good – Excellent (Requires combination with resin base and synthetic label) |

Conclusion: Thermal transfer label paper is significantly superior to thermal paper in almost all dimensions related to durability, and can flexibly cope with various harsh environments by selecting different ribbons and label materials.

How To Make the Right Choice: Thermal or Thermal Transfer?

Choose thermal paper, if:

- Your labels are for short-term use (such as temporary turnover labels in the warehouse).

- The label will not be exposed to high temperatures, sunlight, friction or chemical environments.

- You attach great importance to cost and ease of operation.

Choose Thermal Transfer Paper, if:

- Your label needs to be kept for a long time (more than one year) for traceability or asset management.

- The labels will be exposed to harsh environments (such as outdoors, cold storage, oil stains, friction).

- You need to print high-density barcodes (such as QR codes) or small fonts, and require an extremely high scanning recognition rate.

Summary

In the face of two independent technical routes, the key to decision-making lies in the accurate judgment of the “duration of label information”.

If your label information is “short-lived”, investing in a thermal system is an economical and efficient choice.

If your label information needs to be “durable” or even “permanent”, then investing in a thermal transfer system is the only correct and necessary choice.