Say Goodbye to Faded Labels: Why Telecom Industry Chooses Thermal Transfer Label Printers?

Against the backdrop of 5G network expansion and data center scaling in the communications industry, device and cable numbers have surged, driving demand for thermal transfer label printers. As key “information carriers” for O&M, labels store critical data like device models and port numbers—their clarity and durability directly impact maintenance efficiency.

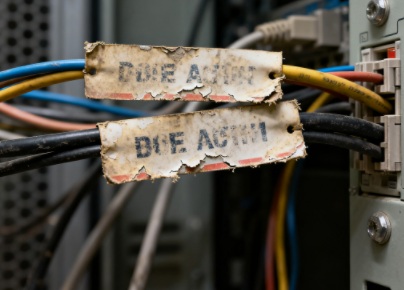

The harsh communications environment (high temperature, humidity, friction, impact, chemical corrosion) easily fades traditional labels; ordinary thermal printers often fail in such conditions, limiting their long-term use. By contrast, thermal transfer label printers create high-adhesion layers via “ribbon transfer”, maintaining clear identification in extremes, making them the most reliable solution.

Chain Harms of Faded Labels

In the telecom industry, labels are used in indoor equipment rooms and outdoor base stations, where harsh environments make fading a common issue. Importantly, fading is not just an “identification problem” but a key bottleneck restricting O&M quality, as it impacts telecom network operations in multiple ways.

High-Frequency Label Fading Scenarios in Telecom

Three scenarios see severe fading:

High temperature/humidity: Outdoor base stations reach over 60℃ in summer and 90% humidity in rainy seasons; indoor equipment rooms have local 35-40℃ due to server heat, with residual moisture seeping labels. Traditional surface ink melts or decomposes, blurring or erasing text.

Friction: Dense cables in rooms are pulled/bent during maintenance; outdoor base stations are inspected 2-3 times monthly, causing frequent friction between hands/tools and labels. Unprotected traditional labels lose ink, making identifiers incomplete.

Chemical erosion: Cleaners/alcohol in rooms react with label ink; oil leaks from old cables in base stations soak labels, accelerating ink dissolution and fading.

Operational Risks from Label Fading

Lower O&M efficiency: Faded labels force staff to spend extra time identifying devices/cables (e.g., testing cables segment by segment). Fault detection takes over 30% longer, and scheduled maintenance (e.g., equipment expansion) also slows down.

Resource waste: To solve faded labels’ identification issue, operators must replace them frequently—every 3-6 months for equipment rooms (1-2 months for base stations), raising material and labor costs. Some replacements require short service interruptions, causing indirect losses.

These pain points have led more telecom O&M personnel to consider adopting thermal transfer labels to replace traditional label printing methods.

How Thermal Transfer Label Printing Solves the Label Fading

Facing label fading in telecom scenarios, thermal printing has limitations due to its principles. However, thermal transfer technology fundamentally enhances label durability via its unique mechanism. Understanding its differences from thermal tech and its “three anti-fading elements” is key to grasping its core advantages.

Unlike thermal printers that rely on paper to develop color, thermal transfer label printers utilize a “ribbon + label consumable” system, which enables significantly higher durability and anti-fading performance—effectively addressing the long-standing label fading challenge in the communications industry.

Why Thermal Transfer Can Resist Fading

Traditional printing’s poor durability stems from flawed ink-substrate bonding, while thermal transfer revolutionizes this to boost fade resistance:

Limitations of traditional printing: It relies on heat to activate color from paper coatings (with pre-applied thermal dyes and developers). No extra ink is needed, but the color layer bonds weakly to the substrate and is sensitive to temperature/humidity—high temp oxidizes it, high humidity accelerates decomposition, and friction damages it. Such labels have short lifespans, failing long-term telecom O&M needs.

Breakthrough of thermal transfer: It uses a “ribbon + label substrate” system. The printer heats the printhead to melt ribbon ink, then presses the melted ink to penetrate the substrate’s surface (even interior). Upon cooling, a stable image forms. Unlike thermal printing’s “surface coloring,” it embeds ink into the substrate, boosting adhesion over 5x. It works with polyester, synthetic paper, PVC (no special coating needed), unlike thermal printing’s reliance on dedicated paper.

So, thermal transfer labels can maintain clear identification in environments such as communication equipment rooms, optical cable nodes, and outdoor base stations, avoiding the short-term failure issue of traditional labels.

Three Anti-Fading Elements of Thermal Transfer Label Printers

The fade resistance of thermal transfer printing stems from a synergistic “protective system” composed of three key elements:

Ribbon material: It adopts an integrated label-ribbon design, centered on high-stability materials. Suitable for telecom scenarios, it resists wear and chemical erosion—withstanding alcohol/cleaner wiping and oil penetration. It maintains ink stability in high-temperature equipment rooms and outdoor base stations with fluctuating humidity, avoiding decomposition or peeling of traditional wax-based or wax-resin mixed ribbons, balancing durability and O&M efficiency.

Label Consumables: It works with multiple consumables to address fading/damage in different scenarios: Smooth PET resists wear, chemicals, water and UV, fitting equipment rooms and outdoor base stations for long-term use. Protective film-coated substrates block oil, solvents, water and friction, designed for harsh outdoor environments. Flexible nylon suits curved cables to prevent ink peeling. Heat-shrinkable tubes are flame-retardant/insulating for high-end cables in high temperatures. PVC resists moisture, chemicals and UV, fitting equipment rooms.

Printing process: Equipped with a 300DPI and efficient printing speed, it enables uniform ink transfer on various substrates. It reduces ink peeling even under cable pulling (equipment rooms) or inspection friction (outdoor base stations), outperforming traditional labels in fade resistance for long-term clear identification.

This system of “ribbon + label consumable + precision print-head” makes thermal transfer label printing the most reliable label printing solution in the fields of communications, network cabling, and equipment asset management.

Practical Advantages of Thermal Transfer Label Printers in the Telecom Industry

The fade resistance of thermal transfer technology is fundamental, but its “customized adaptability” to telecom scenarios enables it to move from “technically feasible” to “practically applicable”. Whether for multi-spec label printing in equipment rooms or on-site O&M at outdoor base stations, thermal transfer printers fit precisely. They also synergize deeply with telecom O&M processes to further boost overall operational efficiency.

Full-Scenario Coverage: Adaptability from Equipment Rooms to Outdoor

Telecom label scenarios mainly fall into “indoor equipment rooms” and “outdoor base stations” with distinct needs. Thermal transfer printers achieve full coverage via “diverse models” and “printing flexibility”. Whether desktop thermal transfer label printers are used for equipment room management, or portable models for outdoor base station inspections, thermal transfer technology can deliver high-quality, fade-resistant printing results.

Multi-spec adaptation for equipment rooms: Equipment rooms have complex labels (cabinet nameplates, cable labels, port labels) with large size differences, plus limited space. Desktop thermal transfer printers—compact, placeable on cabinet tops or workbenches—support 10mm-100mm wide labels. They print both large cabinet nameplates and small port labels, and use “continuous printing + on-demand cutting” to avoid waste, fitting space and multi-spec needs.

On-site printing for outdoor base stations: Base stations are remote and scattered. Transporting pre-printed labels from headquarters risks damage and delays. Portable thermal transfer printers—lightweight, battery-powered, dustproof and waterproof—work in -10℃ to 50℃ outdoor environments. O&M staff print labels on-site based on actual equipment, cutting travel time and improving efficiency.

Efficient O&M Adaptation: Synergy with Telecom Management Processes

Telecom O&M relies heavily on “digital management” (e.g., ERP for resource entry, OMS for task execution). Thermal transfer printers synergize with these processes via “batch printing” and “data integration” to reduce manual intervention and errors:

Fast batch printing for project needs: Large projects (5G base station construction, room expansion) require thousands of labels. Traditional printing is inefficient, but thermal transfer printers support “batch task import”. Staff edit templates on computers, import batch data (e.g., Excel), ensuring project progress.

Data integration to reduce input errors: Label info is stored in systems (ERP, OMS). Traditional printing needs manual copying, risking errors. Thermal transfer printers connect directly to these systems, automatically reading info, generating templates and printing—no manual work. This ensures label accuracy and real-time sync with system updates.

By using thermal transfer label printers linked with data systems, telecommunications enterprises can upgrade label printing from manual operation to digital automatic output, significantly improving efficiency and accuracy.

Final Words

With telecom development and rising O&M needs, they’ve become essential for label management, supporting stable network operation.

In short, thermal transfer printers help the industry shift from “passive label replacement” to “proactive fading prevention,” delivering cost reduction, efficiency improvement and safety. MakeID offers desktop/portable models for equipment rooms, base stations and asset management. Visit MakeID for more models and consumable solutions.