RFID Labels: Are Your Labels Helping You with Inventory Control?

In the present scenario of the telecom industry, inventory goes beyond merely managing the inflow and outflow of stocks. The companies dealing in telecommunications, network service providers, and contractors have to keep track of their assets which are equipment of high value, complex cabling systems, and scattered among warehouses, data centers, base stations, and field sites.

Still, a great number of firms depend on physical documentation or conventional barcode labels only to find that their inventories are in the wrong state—meaning not only that they are inaccurate but also that there is great delay in getting the correct data.

This consequently leads to a very important question:

Do your labels really facilitate your inventory management— or are they the reason for the delay?

RFID (Radio Frequency Identification) labels are gaining more acceptance as a more efficient solution for inventory controls in telecommunication.

Why Inventory Control Is So Difficult in Telecommunications Industry?

Telecommunications inventory has distinguished features that make it very hard to manage:

1. Salable Goods and High Asset Value

A normal telecom inventory comprises:

- Routers, switches, and servers

- Optical modules and transceivers

- Antennas and radio units

- Power equipment and spare parts

- Cables, connectors, and patch cords

Many of the mentioned items are of high value, small in size, and can be easily lost; thus the errors are very costly.

2. Many Places and Routine Emergence

In contrast to traditional manufacturing, telecom assets are in constant movement:

- From main warehouses to regional depots

- From depots to base stations or customer locations

- Back to warehouses for repair or redeployment

To keep accurate records of these movements across The Impossible Locations is a great challenge.

3. Project-Based and O&M-Driven Usage

Telecom inventory is commonly associated with network rollout projects or ongoing operation and maintenance (O&M) procedures. Lack of proper inventory visibility can result in delays in installation, more downtime, and slower service delivery.

What are RFID Labels and How Do They Work in Telecom?

RFID labels are essentially small chips that are embedded in the product and transmit the data wirelessly through radio frequency waves. In comparison to barcodes, RFID does not necessitate the scanning of the item one at a time and permits the reading of several items at once.

Key Components of an RFID System

- RFID label (tag): It is attached either to the equipment or the cables or the packaging.

- RFID reader: It can be a fixed or a handheld device that captures the data of the tag.

- Software system: This system integrates the data with WMS, ERP, or asset management platforms.

RFID vs. Barcode in Telecom Environments

| Feature | RFID Labels | Barcode Labels |

| Line-of-sight required | No | Yes |

| Batch scanning | Yes | No |

| Read speed | Very fast | Slower |

| Suitability for metal environments | High (with anti-metal tags) | Limited |

| Asset-level tracking | Excellent | Basic |

For telecom environments—especially data centers and base stations filled with metal—RFID offers clear technical advantages.

How RFID Labels Enhance Telecom Inventory Management?

Real-Time Inventory Visibility

RFID provides the tracking ability of inventory across warehouses, projects, and field locations to be almost in real-time. The managers can see immediately:

- What assets are on hand

- Where they are

- If they are in use, being transported, or stored

The visibility that comes with it aids in eliminating overstocking and with that comes the reduction of emergency purchases.

Faster and More Accurate Inventory Audits

The traditional method of counting stocks requires the staff to scan the items one by one. On the other hand, RFID permits reading hundreds of labels simultaneously making the counting time and the labor cost dramatically cut down.

The inventory checks that previously lasted days in large telecom warehouses or equipment rooms can now be done in just a few hours.

Reduced Errors and Asset Loss

Human data input and barcode scanning are often error-prone. RFID, however, will be the one to automatically record the data, and this will lead to the following:

- Mislabeling

- Missed scans

- Duplicate records

The above-mentioned reasons will eventually result in less difference between system records and actual stock—and asset loss will be cut down significantly.

RFID Labels’ Advantages for the Telecommunications Sector

Better Inventory Precision

Inventory that is precise guarantees top of the line:

- The right tools are sent with engineers to the areas.

- The network expansion projects will not suffer delays.

- Maintenance crews will easily find the spare parts they need.

In the telecom industry, the accuracy factor has a direct relation to service uptime and customer satisfaction.

Dramatic Reduction of Operational and O&M Efficiency

RFID technology cuts down the time needed for locating, issuing, and returning of equipment. It is even more beneficial when O&M personnel working under tight deadlines due to network faults or upgrades.

Reduced Inventory and Operating Expenses

Better knowledge gives companies the power to do the following:

- Lower safety stock levels

- Refrain from unnecessary purchases

- Reduce chances of having idle or forgotten assets

In the long term, RFID is a major factor in turning inventory from a cost center into a profit-generating strategic resource.

Backing of Digital Transformation

RFID data very well meshes with contemporary telecom technologies like:

- Warehouse Management Systems (WMS)

- Enterprise Resource Planning (ERP)

- Asset life cycle management approaches

The merger of these two through RFID data helps in the areas of smarter planning, predictive maintenance, and data-driven decision-making.

Telecom-Specific RFID Application Scenarios

Telecom Equipment Warehouse Management

RFID does not merely make inbound, outbound, and transfer operations easier but also enhances equipment identification and movement recording in real-time via automation.

Base Station and Data Center Asset Tracking

RFID in base stations and data centers gives:

- Unambiguous asset ownership and responsibility

- Precise lifecycle tracking

- Speedier audits during checks or upgrades

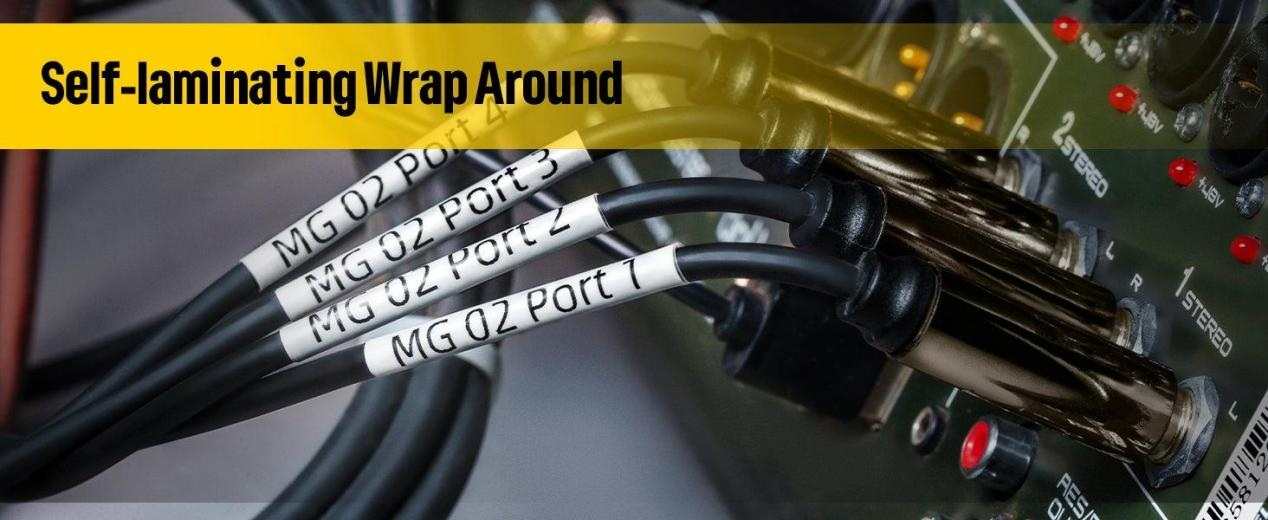

Cable and Wire Identification

Cables are very hard to control. RFID tags meant for wires make it possible for technicians to:

- Recognize types of cables without following

- Cut down maintenance mistakes

- Enhance the accuracy of records

Project-Based Inventory Control

During large-scale rollout projects, RFID helps to ensure that the materials meant for one project are not accidentally used for another—thus, budgets and timelines are protected.

Best Methods for Deploying RFID in Telecom

Select the Most Suitable Type of RFID Label

Usually, telecom situations demand:

- Anti-metal RFID labels for housings of the equipment

- Tags that can withstand high temperatures, and are very strong for the external or power equipment

- RFID labels that can flexibly wrap around the cables and wires

Optimize Tag Placement

Misplacement can make the reading less accurate. Labels should be put in such a way that they will not be shielded and interfered with, particularly if they are on metal surfaces.

Merge with Current Systems

RFID should not work alone. The software for stock and asset management should be integrated so well that it is just like the RFID system is part of that software and thus it gives the benefit of real-time visibility.

Educated Staff and Uniform Process

Good technology is always defeated by bad usage. Setting up clear marking standards and training the staff will make certain data capture is done in a consistent manner in different locations.

Summary

The telecommunications sector has ever-changing and very competitive environment which has made inventory control not merely an operational task but rather a strategic capability. The use of RFID labels can provide real-time visibility, increased precision, and smarter asset utilization over the entire network and different locations in addition to the above-mentioned advantages.

In case your organization is facing inventory discrepancies, slow auditing, or loss of assets, RFID may provide the solution you are looking for.

Telecom firms can take advantage of reliable RFID tags designed for difficult environments and heavy usage with MakeID’s industrial-grade labeling and printing solutions.

The real question is no longer whether RFID works—but whether your current labels are truly helping you manage inventory effectively.