Network Cable Management Ideas: How to Use Tools and Labels to Improve Efficiency

In modern office environments and data centers, network cabling is almost an indispensable part. However, messy network cables not only affect the overall cleanliness of the environment but may also complicate daily maintenance. Without reasonable management, it often takes a lot of time to identify the problem when a network failure occurs. In fact, the root cause of these troubles is not only the lack of proper wiring, but also the absence of professional management tools. Whether it is the wiring of an enterprise’s computer room or the simple network setup at home, suitability has become an important part of ensuring efficient operation and maintenance.

Network Cable Management Tool

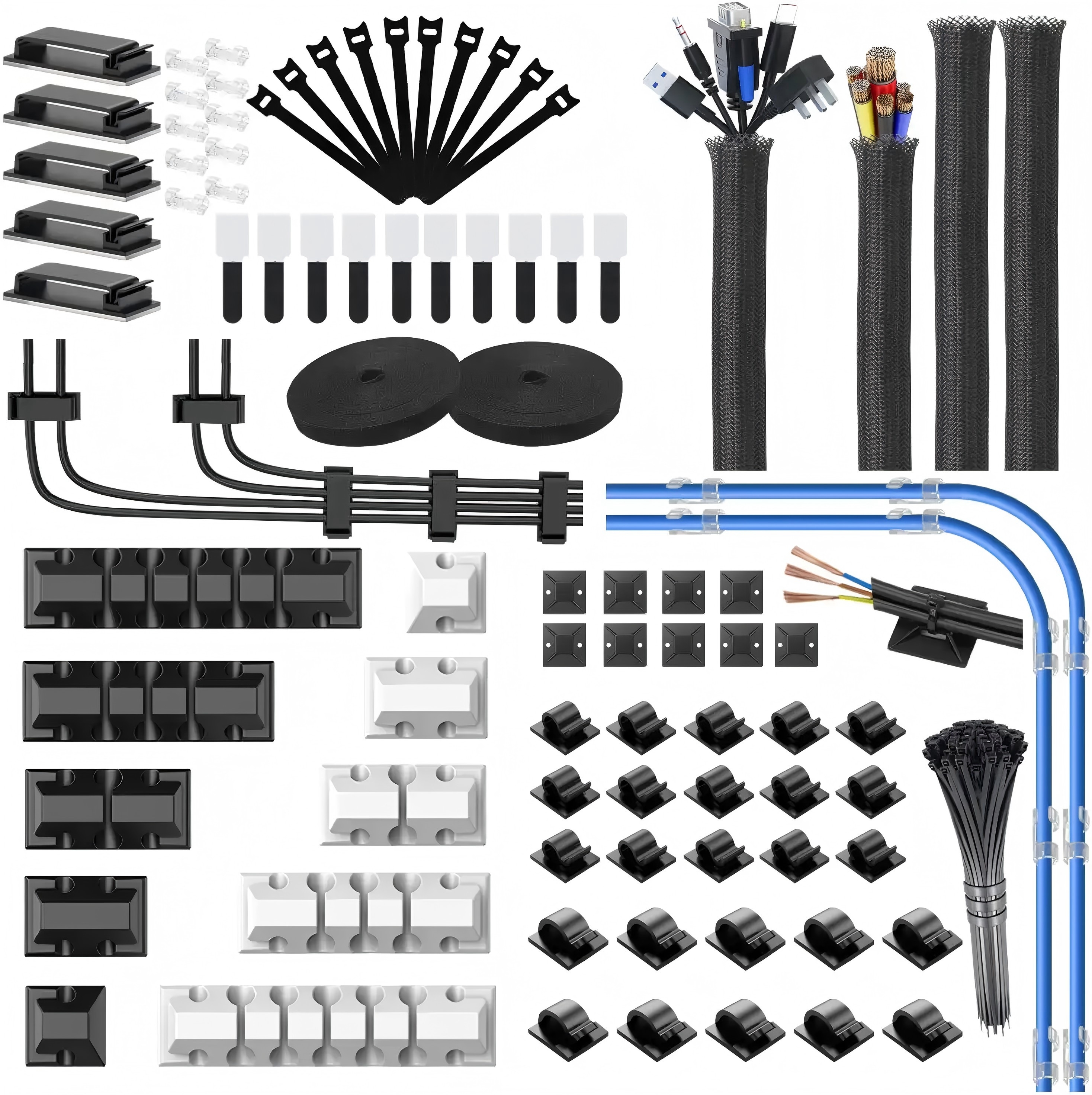

When it comes to network cable management tools, many people’s first reaction is “cable ties”, but in fact, it is only a small part of them. A complete tool system is divided into three categories. Different combinations should be selected for different scenarios. Buying blindly is actually a waste.

1.Tools are classified into three categories, corresponding to different needs

Organizing tools: responsible for “straightening out the wires”, such as reusable cable ties, cable troughs/conduits, cable management racks, and cable storage boxes.

Identification tools: This is the focus of today – label printers and Flag labels, as well as the corresponding tear-resistant and waterproof label paper. Without markings, no matter how neatly arranged the lines are, they will still become unrecognizable after some time.

Auxiliary tools: Help you “handle the details”, such as cable testers, wire strippers, and wire cutters.

2. How to choose for different scenarios?

- Small office/home wiring (10-20 information points) : It doesn’t need to be overly complicated. Cable management racks, reusable cable ties, mini label printers, and small-sized flag labels are sufficient.

- For large-scale data center cabling, professional equipment should be selected, such as cabinet-specific cable managers, industrial-grade label printers, waterproof and high-temperature resistant flag labels, and cable testers should also be provided.

- Outdoor wiring: Focus on “durability”. Choose anti-aging cable trays, flag labels should be waterproof and sun-proof, and portable label printers are preferred for convenient on-site operation.

Label Printer: The “Essential Tool” for Cable Identification

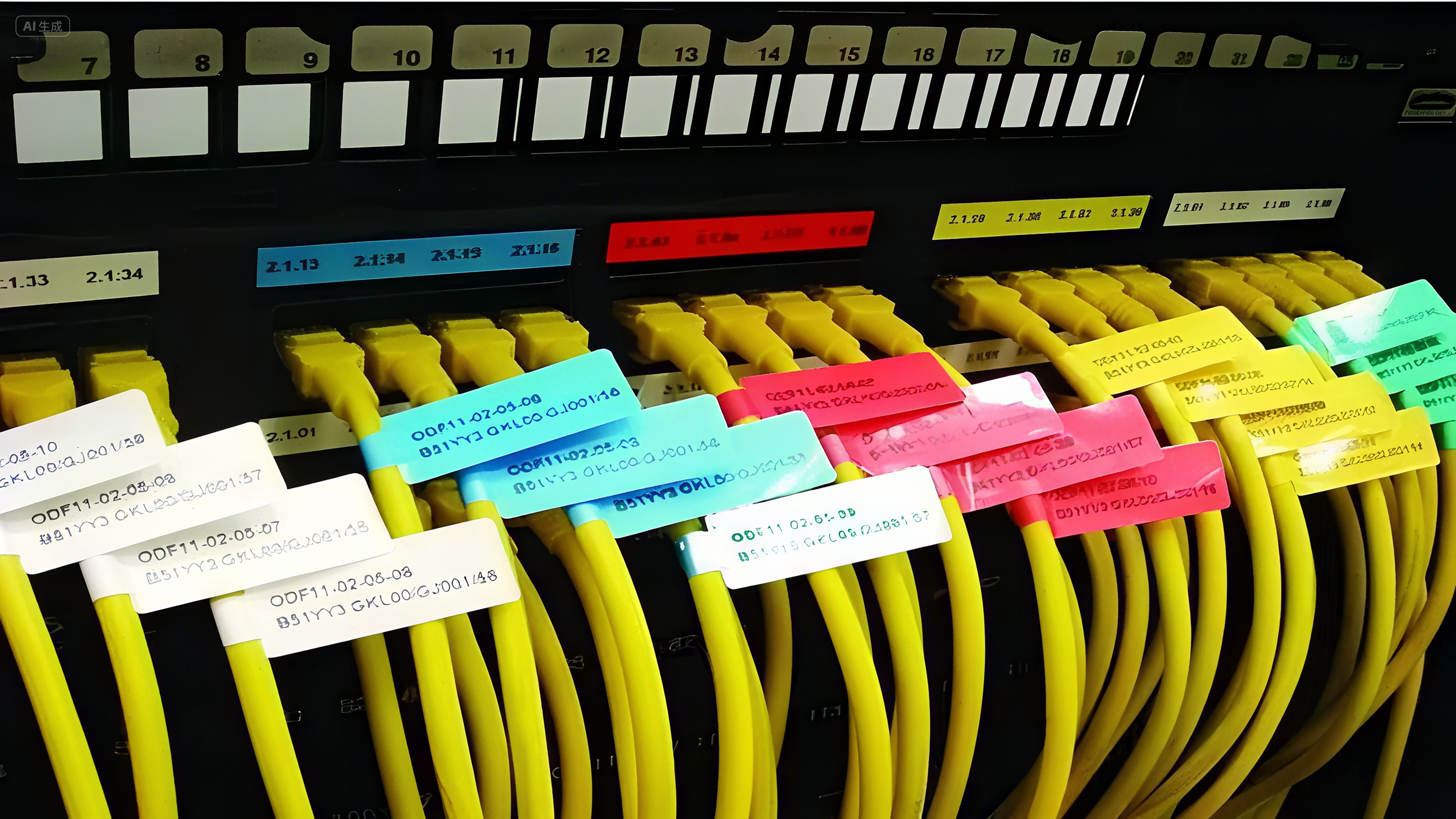

Even if the lines are well-organized, if there are no markings, subsequent maintenance will still encounter difficulties. Imagine standing in front of a cabinet facing dozens of network cables that look exactly the same. How can you quickly find your target? At this point, the importance of labels becomes prominent.

1.Why is it necessary to use a label printer?

- Reject invalid label: Handwriting often leads to inconsistent fonts and incomplete information. Label printers can clearly print cable numbers, uses, and the devices they belong to (for example, “switch A-port 12-financial computer”), which is understandable to everyone.

- High efficiency and durability: It only takes a few minutes to batch print dozens of labels, and the dedicated label paper (such as thermal transfer paper) is anti-aging and oil-proof, and can last for several years after being pasted.

- Compatible with various cables: Whether it’s thick network cables or thin power cords, you can find the corresponding label size, and there won’t be problems like “the label is too big to cover” or “it’s too small to see clearly”.

2. When choosing a label printer, pay close attention to these three points

Print resolution: At least 300dpi should be selected. Otherwise, small fonts like IP addresses and port numbers will be blurry when printed.

Consumable compatibility: It is essential to confirm whether Flag label paper can be used. Otherwise, if you buy a printer but it cannot be equipped with a flag label, it will be in vain.

Portability: If contestants often need to go to the site for wiring (such as weak current Wells or outdoors), they can carry a portable one that can be connected to a mobile phone via Bluetooth for editing. If it is fixed for use in the computer room, the desktop type is more stable.

3. How to choose between the entry-level model and the professional model?

Entry-level model: Suitable for small offices or homes, supports thermal transfer printing, and is compatible with flag label paper of 12mm or less.

Professional model: Suitable for data centers or large enterprises, it uses thermal transfer technology. The labels can withstand temperatures ranging from -40 ℃ to 120℃ and can print wider labels (such as 24mm flag-shaped labels). Even in damp or high-temperature environments, the labels will not fall off.

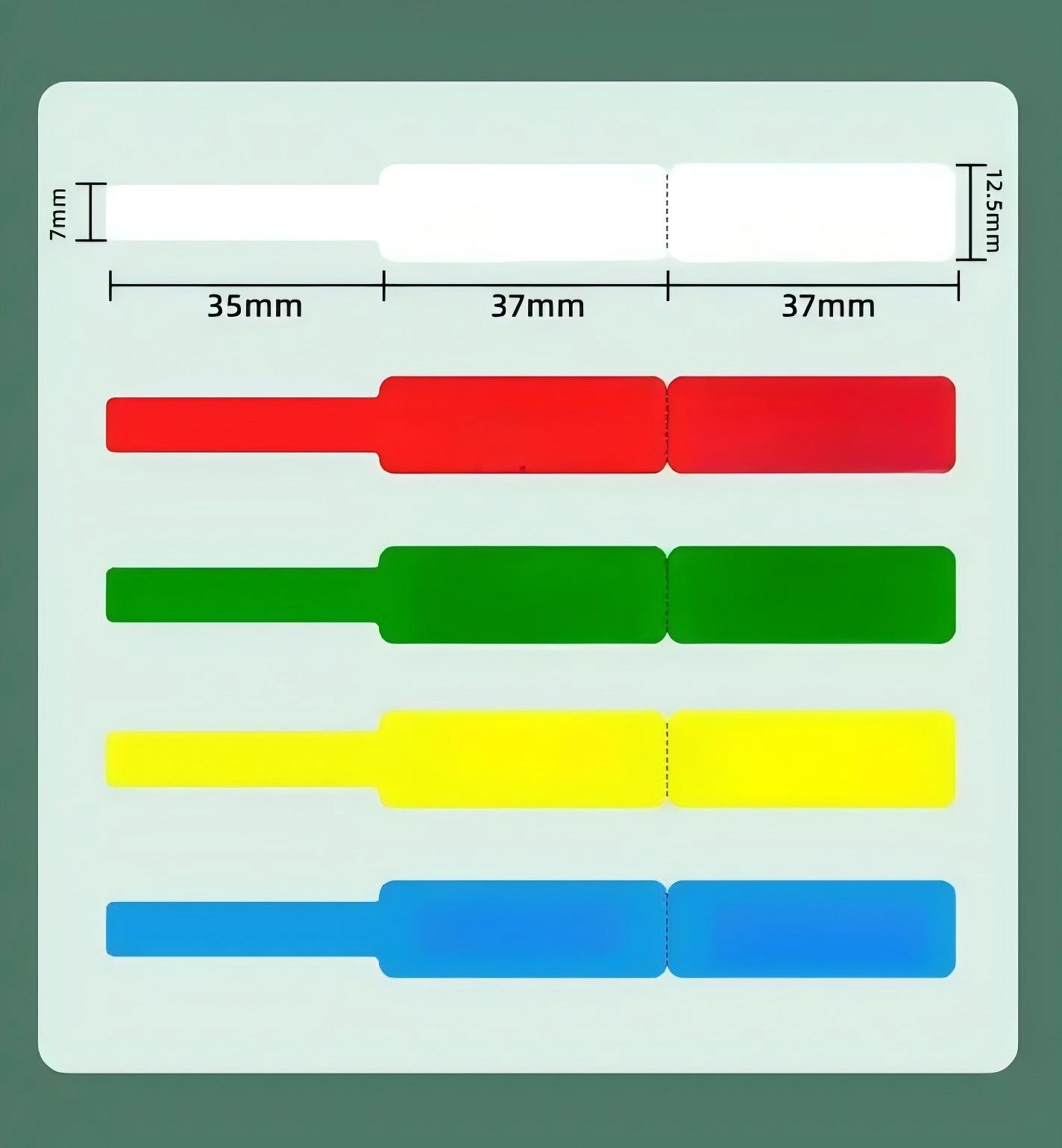

Flag label: The “small flag” of the cable

In daily cabling management, there is another type of label that is particularly suitable for use on network cables: flag labels. Unlike ordinary labels, flag labels fold into a flag shape after being attached to the network cable, making them clearly visible from multiple angles.

1.What are the differences between flag-shaped labels and ordinary labels?

Ordinary labels need to be stuck on the surface of the cables. Once multiple cables are stacked together, if you want to see the labels, you have to pull apart the cables, which can easily loosen the other cables. The flag-shaped label stands upright, like a small flag hanging on the cable. Even if dozens of wires are crowded together, the information on them can be clearly seen without being pulled apart, greatly reducing the risk of accidental touch faults.

In addition, flag-shaped labels have stronger stickiness, and their edges do not curl. Unlike ordinary labels, they do not curl up after being stuck for a long time, making the information unclear.

2. In which scenarios must flag tags be used?

Data center cabinet: A 42U cabinet may contain hundreds of cables. Flag labels are used to clearly indicate “which cable is connected to which port”. When changing equipment or troubleshooting later, there is no need to search for each cable one by one. They can be located at a glance.

Weak current well wiring: The main cables of different floors and areas are all here. Mark them with flag labels as “1st floor Computer room – 3rd floor Sales Department main Line”, so that they won’t be connected wrongly during future expansion.

Outdoor wiring: Choose flag labels that are waterproof and sun-proof. Even if exposed to wind and rain, the words on the labels will not fall off, and there is no need for frequent subsidies.

Best Practice: The combination of tools and labels

To achieve efficient and professional network cabling management, a single tool or method is often insufficient. A systematic approach is:

- First, use network cable management tools such as cable ties, cable trays, conduits, etc. to organize the lines and make the overall direction orderly;

- Use the label printer to print clear and standardized labels to avoid human errors;

- In important or densely populated network cable areas, flag labels are adopted to enhance readability.

Through this combination method, not only can the efficiency of wiring management be enhanced, but it can also maintain clarity and tidiness during long-term use.

Summary: With the right tools, cable management is actually very simple

After reading this, you will find that network cable management is not difficult. The key is to “choose the right tools + do a good job of identification”. Cable ties, cable troughs and conduits are the basic tools for network cable management, and label printers and Flag labels are the “core combinations” among them – without them, even if the cables are neatly arranged, they will still be messy after some time. With them, whether it’s troubleshooting or later expansion, it can be located at a glance, saving a lot of time.

Here’s a small tip for the end: Before purchasing tools, think clearly about your scenario (whether it’s home, office or data center). There’s no need to pursue “the more expensive, the better”. Meeting your needs is the most important thing. In addition, after attaching the labels, it is recommended to check them every six months. If the labels are found to be worn or fallen off, they should be reprinted promptly with a label printer to keep the markings clear.