How Should Network Cables Be Labeled According To Industry Standards?

The Internet is the circulatory system of modern organizations. When a cable malfunctions or new equipment needs to be added, a wiring system lacking effective labels can instantly become a black hole in productivity. According to statistics, up to 30% of the time technicians spend on locating and diagnosing network problems is wasted on tracking down faulty cables. Standardized cable labels are not merely an aesthetic issue; they are also a strategic priority concerning operational efficiency, rapid fault recovery, reducing the mean time to repair (MTTR), and ensuring the long-term maintainability of the network. The ANSI/TIA-606-C standard is precisely a blueprint created to transform this chaos into transparency.

Understanding the ANSI/TIA-606-C Standard: The Foundation of Standardized Cabling

What is ANSI/TIA-606-C? It is the “Telecommunications Infrastructure Management Standard” jointly released by the American National Standards Institute (ANSI) and the Telecommunications Industry Association (TIA). The aim is to provide a unified management solution for telecommunication cabling and space in commercial buildings, data centers and campus networks.

Key management principles: The core principles are uniqueness, consistency, traceability and maintainability.

Five management levels:

- Class 1: Suitable for small facilities in a single telecommunications room.

- Class 2: Applicable to a single building that includes multiple telecommunications rooms.

- Class 3: Applicable to campus networks composed of multiple buildings.

- Class 4 & 5: Suitable for large enterprises and data centers with multiple sites and tenants, emphasizing electronic management and automation.

The main updates and advantages of ANSI/TIA-606-C: Compared with the previous B version, the C version places more emphasis on integration with BIM (Building Information Modeling), supports electronic identifiers such as QR codes and RFID, and has detailed guidance for application scenarios in data centers and intelligent buildings.

Core Elements Of Network Cable Labels (Based On ANSI/TIA-606-C Standard)

The core of the ANSI/TIA-606-B standard lies in providing each component of the cabling system with a unique “identity”. The following are the key elements that constitute a compliance label scheme:

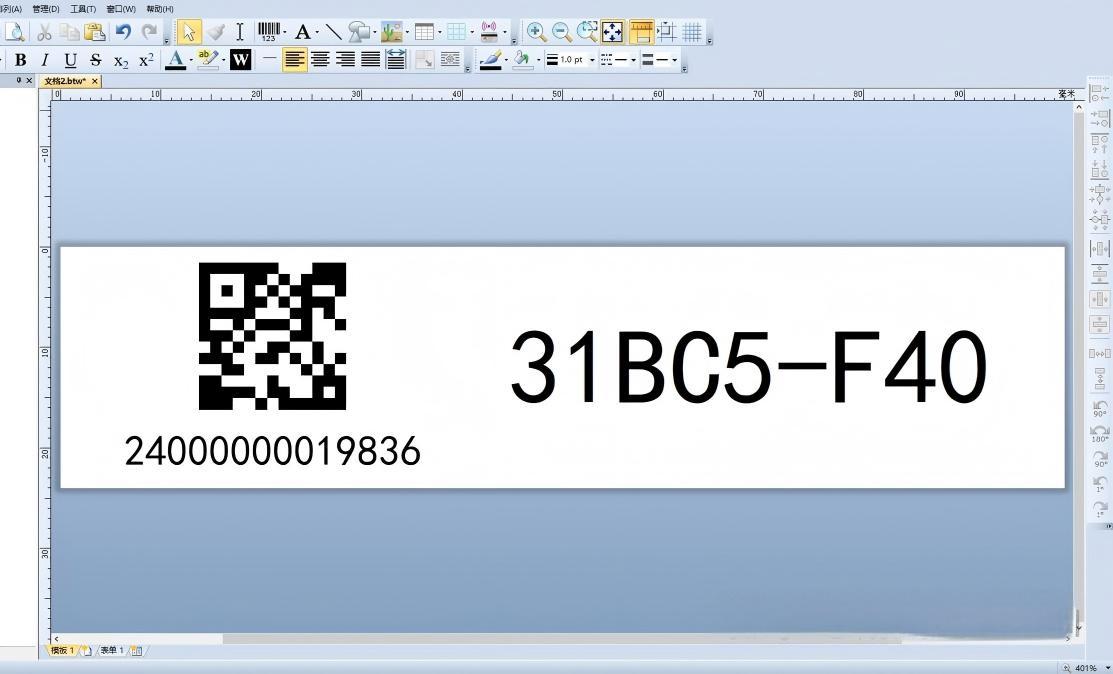

Cable identifier: Assigns a unique identity to each cable

Each cable, patch cord and permanent link should be assigned a unique identifier. This identifier is usually encoded in a structured alphanumeric format, such as A101-Floor2-RJ45-01, which contains location, type and sequence information. Uniqueness is the highest principle, eliminating any ambiguity.

Location marking: Clearly indicate the starting point and the ending point

The label must clearly indicate the origin and destination of the cable. This includes:

- Equipment Room (ER)

- Telecommunication Room (TR)

- The information socket in the workspace (WA)

The positions of cabinets and patch panels in the data center

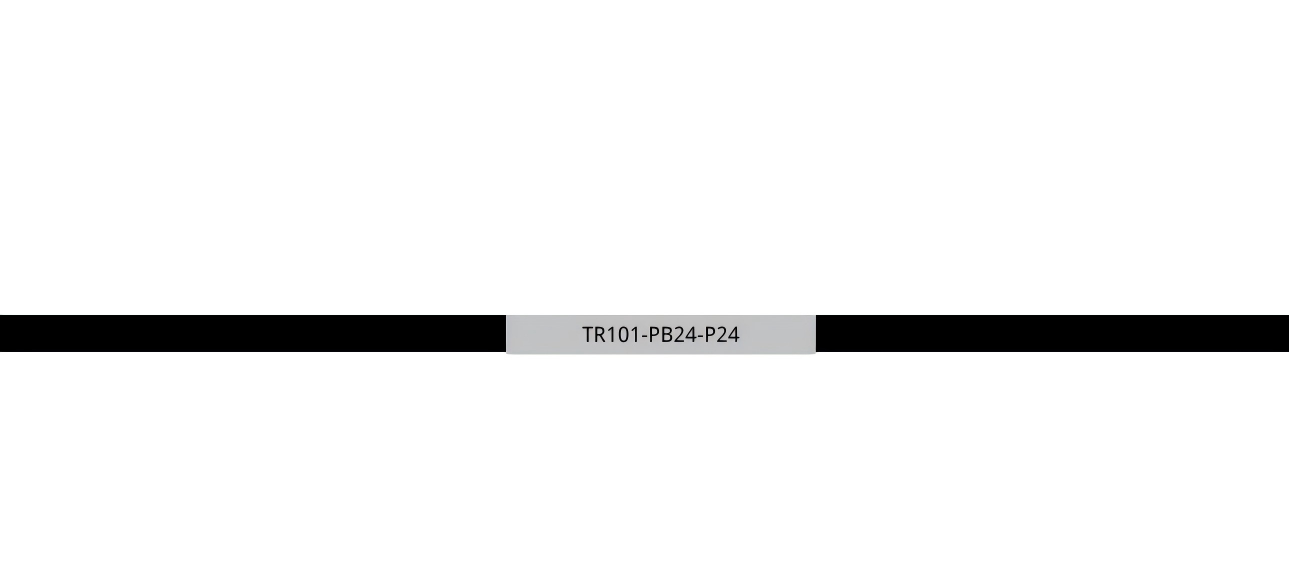

The standard location identification format, such as TR101-PB24-P24, indicates “Telecommunication Room 101, 24-port patch panel, port 24”.

Color coding: Enabling rapid visual recognition

Color provides the most intuitive visual cues for quickly distinguishing cable types, functions or the network areas they belong to. ANSI/TIA-606-C recommends the following color schemes (examples) :

| Color | Pantone color codes | Function |

| orange | 150C | demarcation point |

| green | 353C | Network connection (such as campus network trunk) |

| purple | 264C | General-purpose equipment (dedicated small switches (PBXs), computers and local area networks) |

| white | – | Primary main trunk cable |

| Grey | 422C | Secondary main trunk cable |

| blue | 291C | Horizontal cabling (work area connection |

| brown | 465C | Mark the main cables between buildings |

| yellow | 101C | Auxiliary circuits, alarms or safety systems |

| red | 184C | Critical mission or emergency response systems |

Uniform color coding enables people to understand the basic purpose of cables within seconds.

End Contact Label: Ensure the clarity and accuracy of the connection points

The label must be applied to all end points, including patch panel ports, information modules (sockets), and device ports. The labels at both ends of the patch panel (cross-connection and interconnection points) must correspond to each other to ensure that the entire path from the work area socket to the network switch is traceable.

Cable type and category identification

Although the unique ID is the core, it is also a best practice to indicate the type of cable (such as Cat6A, OM4, Single-Mode) in the label or record, which is crucial for maintenance and upgrades.

Specific label requirements for different infrastructure components

The standard has specific label regulations for patch panels, grounding wires, optical cables, power lines, etc., to ensure the unified management of the entire infrastructure.

How to Create And Apply Compliant ANSI/TIA-606-C Labels

Having understood the core elements, the next step is to put them into practice.

Plan your tagging scheme: Design and strategy first

Naming convention: Before commencing construction, design a set of logically clear and extensible naming rules. Consider the combination of geographical location (building, floor, room), functional area and serial number.Select the management level: ANSI/TIA-606-C defines five management levels from 1 (simple) to 5 (complex). Choose the appropriate level based on the scale and complexity of your network (such as small offices vs. large data centers).

Best practices and quality requirements for label creation

Material: Select label materials suitable for the environment. Vinyl can be used indoors, while durable polyester or laser-readable labels are required in data centers or industrial environments.

Print quality: Professional label printers are used to ensure that the text and barcodes are clear, wear-resistant and anti-fading. Avoid handwritten labels.

The content should be concise and clear, containing all necessary information, but avoid being overly crowded.

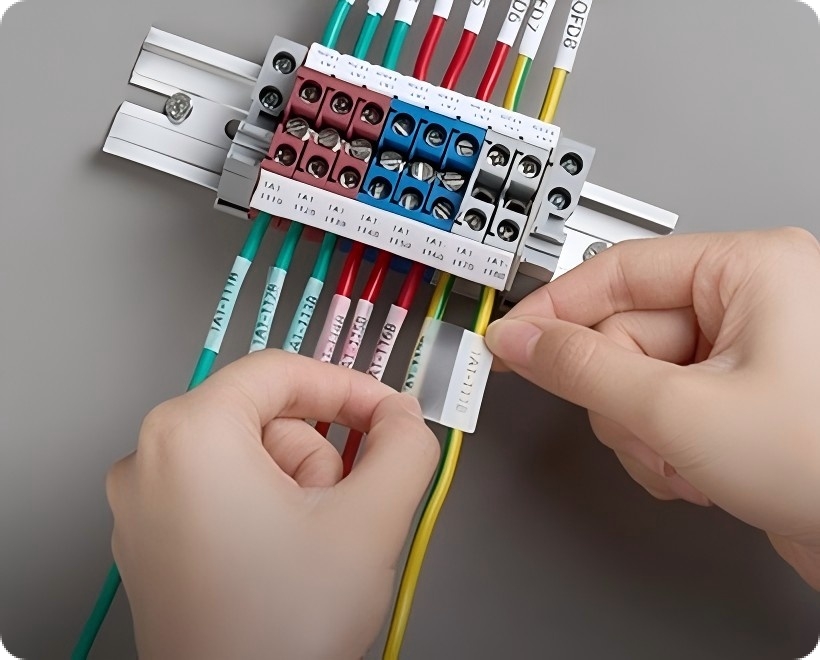

Application tip: Ensure the best visibility and persistence of the label

Location: Apply the label in an easily visible position, usually near the end junction. For jumpers, the ideal position is about 2 inches (5 centimeters) from the label to the connector.

Direction: Ensure that the text direction is parallel to the cable for easy reading.

Fixation: Use wrap labels or label flags to ensure they are firmly attached and will not loosen or fall off during cable movement.

Documents and Records: The Cornerstone of ANSI/TIA-606-C Compliance

The tag system itself is just the tip of the iceberg; its value entirely depends on detailed documentation.

The record-keeping regulations required by the standard: ANSI/TIA-606-C mandates the maintenance of records for all identifiers, including cable paths, termination points, test results, and change histories.

Effective record management tools: From simple spreadsheets to professional infrastructure management (DCIM/IaM) software (such as Nlyte, Sunbird DCIM, iTracs), the choice of tools depends on the management level.

Youdaoplaceholder0 Benefits of record-keeping: Accurate documentation enables “desktop” troubleshooting, significantly reduces maintenance time, and provides data support for network planning and expansion.

Advanced Considerations And Best Practices

Expansion strategy for large-scale deployments: In data centers, it is crucial to adopt a hierarchical identification scheme of “row – column – cabinet – patch panel – port”.

Integration and future verification: Design the tag system as part of the broader TIA-942 (data center) and TIA-568 (cabling) standards, and reserve identification space for future expansion.

Third-party certification: In large-scale projects, engaging a third party for compliance certification can ensure that the label and documentation systems fully comply with standards, providing a guarantee for investment.

Tools and Materials for Achieving ANSI/TIA-606-C Compliance

Label printer: MakeID’s industrial-grade printer EP53 is a reliable choice.

Cable label type

- Wrap label: The most commonly used, providing full-cycle visibility.

- Label flag: Suitable for jumpers and easy to identify at dense ports.

- Heat shrink tubing label: Offers excellent protection and permanence.

Software: Professional Label design software (such as MakeID Label Pro) or the label module in DCIM software can ensure the uniformity of format and the accuracy of content.

Conclusion

Network cable labeling standardization brings more than just a neat appearance; it reduces operating costs, improves network availability, and enhances agility in responding to future changes. When your cable system transforms from “nobody knows which cable is which” to “clear and transparent,” you gain access to an invisible yet incredibly powerful productivity tool, laying the most solid physical foundation for your digital business.