How Label Material Affects Print Clarity

In applications such as barcode labeling, product identification, and logistics management, print clarity directly impacts information recognition efficiency and scan success rate. Many users, when optimizing print quality, often focus only on printer performance or ribbon quality, neglecting a fundamental yet crucial factor—the label material itself. In fact, differences in surface structure, ink absorption, and heat resistance among various label materials significantly affect the clarity of text and barcodes.

Key Factors That Influence Label Print Quality

The impact of label materials on printing quality is mainly reflected in the following aspects:

- First, the surface coating structure. Coating density determines whether the ink or ribbon layer can adhere stably and maintain clear line edges.

- Second, ink absorption and color development capabilities are crucial. Excessive absorption leads to ink diffusion, while insufficient absorption may result in incomplete adhesion.

- Third, material flatness and thickness consistency directly affect the uniformity of heat distribution to the print head.

- Furthermore, heat resistance is particularly critical for thermal and thermal transfer printing.

- Finally, color and reflectivity affect visual contrast and barcode readability.

These factors collectively determine the final level of print clarity.

How Different Label Materials Impact Print Clarity

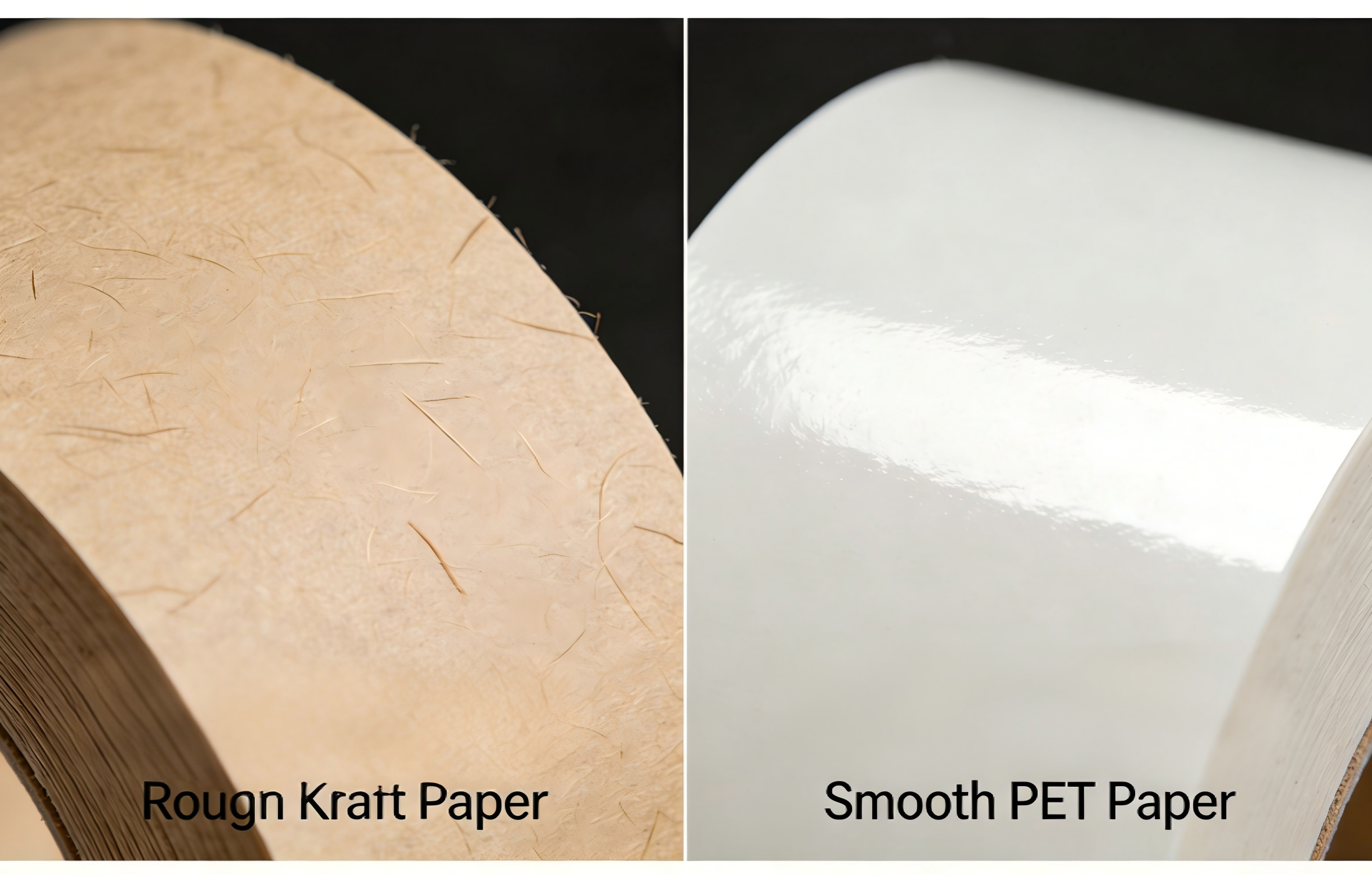

Clarity performance of uncoated paper labels

Uncoated paper is usually made by directly pressing natural paper fibers. It has many microporous structures on the surface. During printing, the ink tends to quickly penetrate and spread outward, resulting in blurred text edges, thickened barcode lines, and even adhesion.

Although this material is inexpensive, it performs poorly in high-density barcodes and fine-font printing. It is more suitable for simple text or temporary identification applications. If high-definition output is desired, uncoated paper is often not an ideal choice.

How can coated paper labels achieve high-definition printing results?

Coated paper undergoes a special resin or chemical coating treatment, forming a smooth and dense printing layer that effectively limits ink diffusion. Printed lines remain sharp and clear, with significantly improved contrast.

Common coated labels include glossy coated paper and thermal coated paper. These materials are widely used in retail, logistics, and warehousing, and are particularly suitable for labels with barcodes and dense small-font information.

Due to their stable color development performance, coated labels often significantly improve scan success rates and are a common solution for enhancing print clarity.

High precision performance of synthetic label materials (PET, PP, PVC)

Synthetic materials such as PET, PP and PVC have extremely smooth surfaces with almost no paper fiber pore structure. During the printing process, the ink layer mainly adheres to the surface coating and does not cause penetration and diffusion problems, thus enabling extremely high line clarity.

These materials are particularly suitable for:

- High-density QR codes and fine line barcodes

- Product identification for long-term preservation

- High-precision applications in industrial environments

Among them, PET labels are particularly common in electronic manufacturing and equipment identification due to their excellent heat resistance and stability.

Material Requirements for Thermal and Thermal Transfer Printing

Thermal Printing’s Dependence on Coating Quality

Thermal printing relies on the direct development of color through a thermal coating upon heating. Uneven coating distribution or low quality can easily lead to:

- Inconsistent color depth

- Localized graying

- Blurred character outlines

High-quality thermal paper possesses rapid color development, high blackness, and uniform reaction characteristics, significantly improving print clarity and stability.

The Importance of Material and Ribbon Matching in Thermal Transfer Printing

In thermal transfer printing, the ribbon melts and transfers the ink layer to the label surface. If the material’s heat resistance is insufficient or the coating adhesion is poor, the ink transfer will be incomplete, resulting in broken lines, faded colors, and other problems.

Common matching relationships include:

- Coated paper + wax-based or mixed-based ribbon

- PET, PP synthetic materials + resin-based ribbon

Properly matching materials and ribbon types is a crucial prerequisite for achieving high-definition printing results.

Comparison of Clarity Performance Of Common Label Materials

There are a wide variety of label materials available on the market, each with different printing methods and clarity performances.

| Material Types | Supported Printing Methods | Clarity performance | Applicable scenarios |

| Coated Paper (Self-adhesive) | Thermal Transfer | Excellent: Smooth surface, even ink absorption, high clarity for small fonts and barcodes. | Short-term indoor scenarios such as supermarket price tags, ordinary logistics labels, indoor paper signs, etc. |

| Thermal Paper | Thermal Printing | Good to Excellent: High-quality product with sharp lettering edges. | Scenarios for rapid printing such as express labels, takeout receipts, temporary supermarket labels, hospital receipts |

| PET Synthetic Paper | Thermal Transfer | Excellent: Smooth surface, dimensionally stable, wrinkle-resistant and tensile-resistant. | Labels for the electronics industry, chemical industry, industrial production lines, with high precision and resistant to weather and tearing |

| PP Synthetic Paper | Thermal Transfer | Good to Excellent: Good toughness, relatively good flatness. | Labels for food, daily chemical products, products for short-term outdoor use |

| Matte Synthetic Paper | Thermal Transfer | Good: Matte surface, non-reflective, visually comfortable. | Labels for high-end cosmetics, gift boxes, electronic products, etc., with requirements for appearance |

How can we improve print clarity by choosing the right label materials?

For different application scenarios, the following material selection guidelines can be considered:

In electronics manufacturing and industrial applications, PET synthetic labels are more suitable for high precision and durability requirements.

In the retail and medical sectors, high-contrast coated labels help improve information recognition efficiency.

In logistics and warehousing, coated paper or high-quality thermal paper can balance cost and clarity requirements.

The general principles are:

- Prioritize coated paper or synthetic materials for high-precision information.

- Choose PET or PP labels for high environmental stability requirements.

- Basic paper materials can be used for general temporary labeling.