How Does A Label Printer Work? Understand The process From Instructions To Labels

The price tags of goods you come into contact with every day, the QR codes on express delivery waybills, the inventory labels in warehouses, and even the numbers on medical devices – all these precise labels rely on the support of label printers. But you might wonder: how does a label printer work? How do these printers clearly print text, barcodes, QR codes and patterns onto labels in just a few seconds? Today, we will comprehensively analyze the working mode of label printers from principle to application.

Core Principle: Thermal sensitivity and thermal transfer technology

The vast majority of industrial and commercial label printers are based on two core technologies: “thermal printing” and “thermal transfer printing”. They all rely on “heat” to manifest, but the paths are completely different.

(1)Direct Thermal printing

Working principle: The print head is rich in tiny heating points, which are selectively heated according to the content to be printed. When thermal paper (a type of paper that has undergone special chemical treatment) comes into contact with a heated print head, the heated part undergoes a chemical reaction and turns black, thereby revealing text, barcodes or images.

Features: No carbon ribbon or ink cartridge is required, and the structure is relatively simple. However, the printed labels are not durable. They tend to turn black or fade easily when exposed to sunlight, high temperatures or friction for a long time. It is commonly seen in short-term applications such as express delivery waybills, retail receipts, and temporary warehouse signs.

(2) Thermal Transfer printing

Working principle: The print head is also heated, but the heat first acts on a ribbon called a “carbon ribbon”. One side of the carbon ribbon is coated with solid ink. When heated, the ink melts and is transferred to the label material below (which can be paper, PET, PVC and other materials), forming a lasting image.

Feature: Carbon ribbons are required. The printing effect is extremely durable, waterproof, oil-proof, resistant to chemical corrosion and scratches, and can be preserved for several years or even longer. It is widely applied in scenarios that require long-term preservation, such as product identification, asset labels, circuit board labels, and outdoor labels.

Label Printer Work Process – 4 Steps

From instructions to printing out labels, the entire process can be summarized into four core steps:

Step 1: Create & Design

Users can design and layout the label content by connecting to label design software on their computers or mobile devices (such as professional software like BarTender and Nicelabel, or software provided by printer brands like MakeID-Life). You can add text, barcodes (one-dimensional codes/two-dimensional codes), serial numbers, pictures, and logos, and freely set the font, size, and layout.

Step 2: Data Transfer & Processing

After the design is completed, you click “Print”. The software will convert the designed page layout and data into an instruction set that the printer can understand and send it to the printer through interfaces (such as USB, Wi-Fi, Bluetooth, NFC).

Step 3: Printing Execution

Processor-driven printing mechanical device

Motor rotation: It drives the rubber roller to precisely convey the label paper and carbon ribbon forward (if in thermal transfer mode).

Print head heating: The processor controls thousands of tiny heating points on the print head to heat up and cool down rapidly as instructed, “drawing” the preset content on the moving label.

(Thermal transfer) Ink transfer: In the thermal transfer mode, the melted ink is precisely transferred from the carbon ribbon onto the label.

Step 4: Label processing (label Finishing)

After printing is completed, depending on the preset and printer configuration, there may be different processing methods:

Tearing paper mode: The label is sent out and the user manually tears it off from the backing paper for use.

Cutting mode: The built-in cutter of the printer will automatically cut the entire roll of labels into individual sheets.

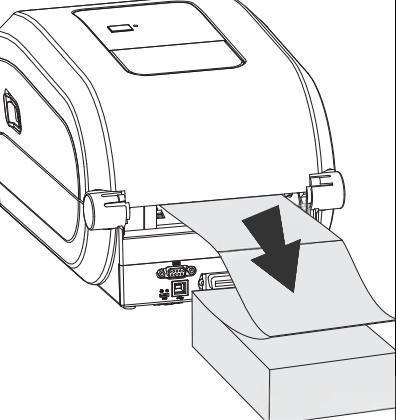

Peel mode (commonly seen in gap labels) : The printer peels off a small part of the printed label from the backing paper, making it convenient for users to directly take and stick it.

Brain And Brush: The Importance of Supporting Software

The printer is the body, while the accompanying software is its brain and paintbrush.

Powerful label design software can achieve:

- Database connection: Directly connect to Excel, SQL databases, etc., to achieve batch variable data printing (such as a unique serial number for each product).

- Automation and Integration: Integrated with business systems such as enterprise resource planning (ERP) and warehouse management system (WMS), it automatically triggers printing tasks and eliminates manual input errors.

Compliance assurance: Pre-set industry standard templates (such as GS1 standards, medical UDI, logistics labels) to ensure that the printed content complies with regulatory requirements.

Ubiquitous Application Scenarios

The work achievements of label printers permeate every corner of business:

Cable identification: Used in data centers, computer rooms and outdoor optical fiber networks, it prints labels containing optical fiber type, port number and path information. The labels are required to be bendable and tear-resistant.

Device labels: Durable labels that attach asset numbers, IP addresses, and configuration information to devices such as routers, switches, and servers.

Safety and warning labels: Important safety tips and operation guidelines for base stations and machine rooms.

Cable terminal marking: Print high-temperature resistant and flame-retardant labels to clearly indicate the phase sequence (A/B/C/N/PE), starting and ending points of power cables, ensuring electrical safety and maintenance efficiency.

Power equipment asset labels: Attach QR code-containing labels to high-value assets such as transformers, distribution cabinets, and circuit breakers to enable rapid inspection, maintenance, and life cycle management.

Safety compliance labels: Print hazard warning labels, high-voltage warning labels, and lock and tag (LOTO) labels that comply with industry safety standards.

Industrial MRO (Maintenance, Repair, Operation)

Tool and spare parts Management: Print labels with unique numbers and information for precision tools and maintenance spare parts to achieve borrowing and returning tracking of tools and inventory management of spare parts.

Safety inspection point labels: By attaching labels to key points of the equipment, inspection personnel can scan the QR code to record the status and report potential hazards, achieving predictive maintenance.

Pipeline valve marking: Print labels that are resistant to chemical corrosion and oil stains, clearly indicating the medium inside the pipeline, flow direction and the opening and closing status of the valves. This is the foundation for the safe operation of the factory.

Logistics and warehousing: Express delivery waybills, warehouse location labels, inbound and outbound labels, handling instruction labels.

Manufacturing and industry: Product nameplates, asset tracking management, safety warning labels, circuit board identification.

Medical and health care: Drug labeling, test tube sample labels, UDI labels for medical devices, patient wristbands.

Office and Life: Document archiving, asset labels, address labels, personal item identification.

Summary

A label printer is an efficient device that precisely converts digital instructions into physical labels through thermal or thermal transfer technology. Combined with powerful supporting software, it has become a key bridge connecting the virtual and the real in the digital management of enterprises.

No matter which industry you are in, as long as you need accurate, efficient and professional marking solutions, a suitable label printer is an indispensable and capable assistant for you.

If you have any questions about how to choose the label printer or software that best suits your business needs, our expert team is always ready to provide you with free consultation and solutions!